- What is the Digital Factory?

- Digital Factory is a technological and human alliance

- The digital factory, or digital factory, is based on 6 human values and 5 technological pillars

- The 6 human values of a digital factory

- The 5 technological pillars :

- Find the 3 key stages of a digital Factory in Digital transformation in 3 stages.

To improve their speed to market of value-added products and services and, above all, to be closer to the needs of their customers, companies driven by their need to innovate and transform their manufacturing process into digital products are embarking on transformation programs, with the program a profound upheaval of their managerial strategy and their process .

This digital transformation, once completed, is known as the digital factory.

What is the Digital Factory?

The digital factory is based on human values and technological pillars. It replicates aspects of a physical factory using a network of digital models, methods and tools, all of which are managed by integrated data management systems. These methods and tools also include simulation and 3D visualisation.

The innovative, open, autonomous mindset is a necessary space to innovate and structure a value proposition between humans and robots, to make a Digital Factory work in the long term.

It is also a place, encouraging the meeting between experts, facilitating experimentation and internal innovation as a “booster” of the digital transformation of all the businesses of the company.

What is the digital factory based on?

To implement a Digital Factory, strategic management must take into account existing skills, market needs and the state of its production site.

The Digital Factory is a factory whose main mission is to integrate digital innovations to make manufacturing processes work.

It represents the industry of the future. But that future is already here. Industry has become a chain of creation, production and new uses in perpetual revolution.

After the transformation of the design process, collaborative tools for managing multi-site production are being put in place, integrating robotics and conversational technology as the primary interface between man and machine.

The challenge is to better control production costs, real-time production, remote maintenance, etc. The Digital Factory integrates innovation and performance.

It is also a place that encourages meetings between experts, facilitating experimentation and internal innovation as a “booster” for the digital transformation of all the company’s businesses.

Digital Factory is a technological and human alliance

In my Digital et humain article, I invited strategic management to make a choice:

1- I build my digital, immersive or digital business journey. Humans will adapt to AI *

2- I am building my organization for humans, intra-humans. All digital tools and AI * adapt to humans to simplify processes and enrich their daily lives.

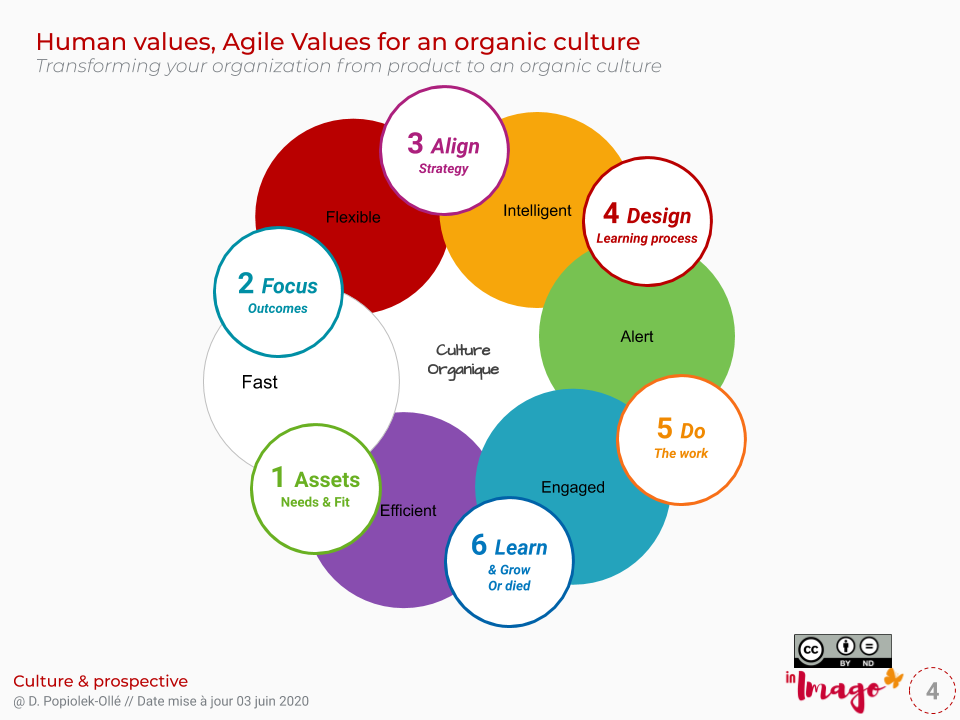

The digital factory, or digital factory, is based on 6 human values and 5 technological pillars

The 6 human values of a digital factory

To set up a digital factory, strategic management must take into account existing skills, market needs and the state of its production site

Adopting Agile values is an asset in addition to strategic management to ensure that the teams in place will be autonomous and efficient in the implementation of the Digital Factory.

The innovative, open, autonomous state of mind is a necessary space to innovate and structure a value proposition between humans and robots, to make a digital factory work over the long term.

The 5 technological pillars :

1- The cloud: access to the Cloud with secure access must be designed to allow access to collaborative tools while facilitating the collection of data within the digital Factory.

2- Advanced robotics: advanced robotics makes it possible to reproduce identically certain human gestures such as the articulated arm, handling gloves …

3- connected objects: the processes will have been simplified to promote the integration of connected objects in predictive maintenance and facilitate the location of the machine and the part affected on a remote computer.

4- Artificial intelligence, A.I: AI allows the implementation of collaborative robots taking place certain aspects of the process and interactive dialogue with the people in charge of the production process

5- Big data: Big data is all the digital data that passes through information systems – IS, whether internal (emails, document management, purchases, etc.) or external on social networks for example.

Find the 3 key stages of a digital Factory in Digital transformation in 3 stages.

Author: Dominique popiolek-Ollé, Transmutation leader, Agile Executive Coach, Founder of In Imago management consulting and disruptive transformation.