Lean management started hunting down the unnecessary from the middle of the 20th century.

Lean could be summed up as follows: Focus on creating value, eliminating waste by developing the talent of its employees to always better satisfy its customers and prepare to win new ones.

Lean is a structured system based on continuous improvement and customer satisfaction. Over the past 30 years, as part of the Lean movement or other trends in management, organization and quality: these two concepts have been widely developed and implemented around the world in all kinds of variations, tools and methods.

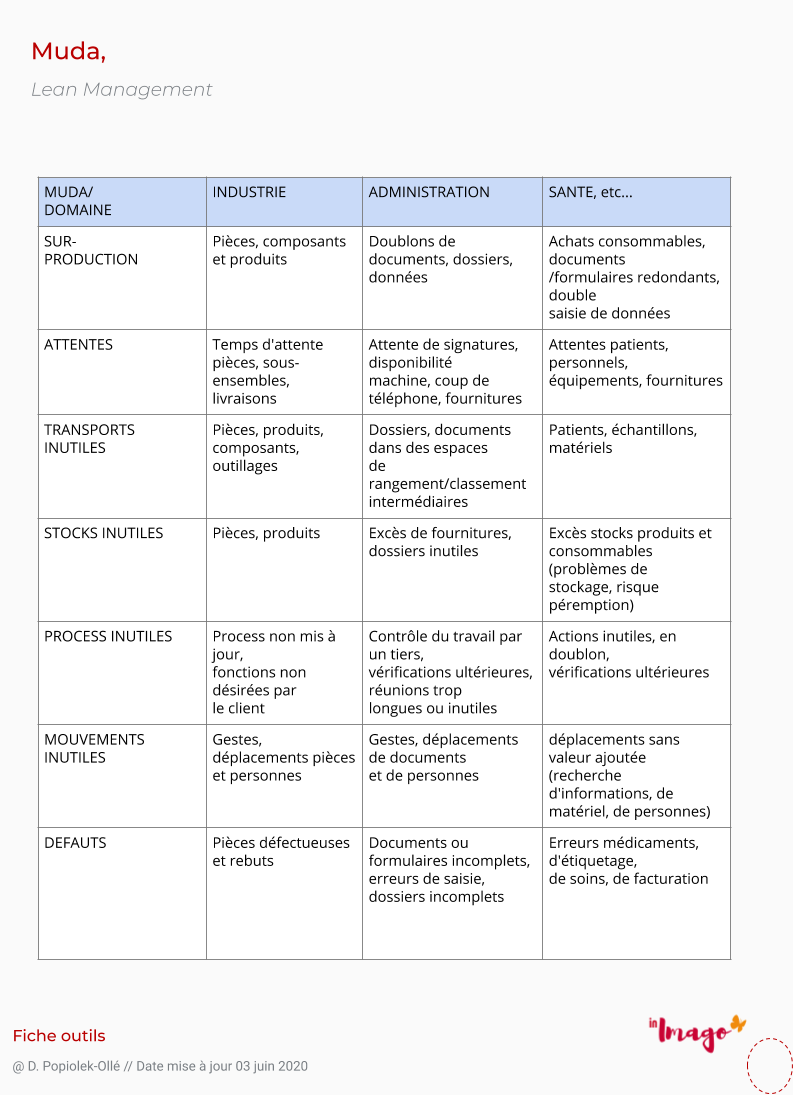

The japanese associated term is Muda (無駄?) which means « unnecessary ». The first 7 wastes are:

The 7 Muda :

1- Overproduction

2- Delays

3- Unnecessary transport

4- Unnecessary stocks

5- Unnecessary process

6- Unnecessary movements

7- Defects

At the basis of Lean, 5 principles that will serve as a basis to create a virtuous loop with the 3M – Muda, Mura, Muri:

Muda have translations in all areas and sectors of the company (see table below). These 7 Muda are associated with:

Mura, which means variation. It is the ups and downs of production and all the irregularities of flow that require the establishment of buffer stocks and work in progress.

Muri, which means that is excessive, unreasonable. This includes excessive effort, overwork (of men and equipment). Quality of life at work, is taken into account early on by strategic management.

The 8th Muda, human waste

Taïchi Ohno will quickly add an 8th Muda the waste of human resources.

On this last Muda, I invite you to read Pierre Noël Giraud’s book, “The useless man“, a call to the collective conscience to reduce inequalities in the face of work: “Uselessness is a particularly serious and resistant form of inequality, because it locks in traps from which it is very difficult to escape? “

The Muda, Mura, Muri are taken into account in the analysis of the strengths and weaknesses of the company according to the strategic line defined by the strategic management.

The 3 M are the pillars of Toyota’s management system, as defined by Taïchi Ohno.

This gives birth to Lean Manufacturing, Lean Mangement, Lean Sigma.

This inspired the Agile movement and the Agile Manifesto which, from the start of the project, focused on the essential, what is necessary for the client. In Agile, by successive iteration, in a short loop of continuous improvement, the team delivers customer value, normally without unnecessary development and without waste.

Agile in this sense, revolutionizes the project by focusing directly on customer added value and not on the value delivery process.

Useless! Get rid of it and get to the point: simplicity.

In my first team support, when the team took pleasure in throwing away what was not achieved in its visual management, I knew that the support was coming to an end. The team then understood principle number 10 of the Agile Manifesto: the art of maximizing the work not done!

The elements in the parking lot, the “nice to have” developments that please only the developer, the sea snakes and other hot potatoes that nobody wanted, could thus be simplified or thrown away.

The ideas collected on post-it or wall frieze that we keep: one day perhaps because there were really cool things, but lack of time, it remains as a post-it. Chasing the useless and managing by value allows us to chase the useless.

The Muda by sector of activity

High-tech, digital companies are willingly not quoted. By nature, they are Agile and integrate the Agile Manifesto from the start, and in particular apply the principles 9,10,11 …

See our interpretation of the Agile Manifesto and its 12 principles, and

Author : Dominique popiolek-Ollé, Transmutation leader, Agile Executive Coach, Founder of In Imago,management consulting and disruptive transformation.